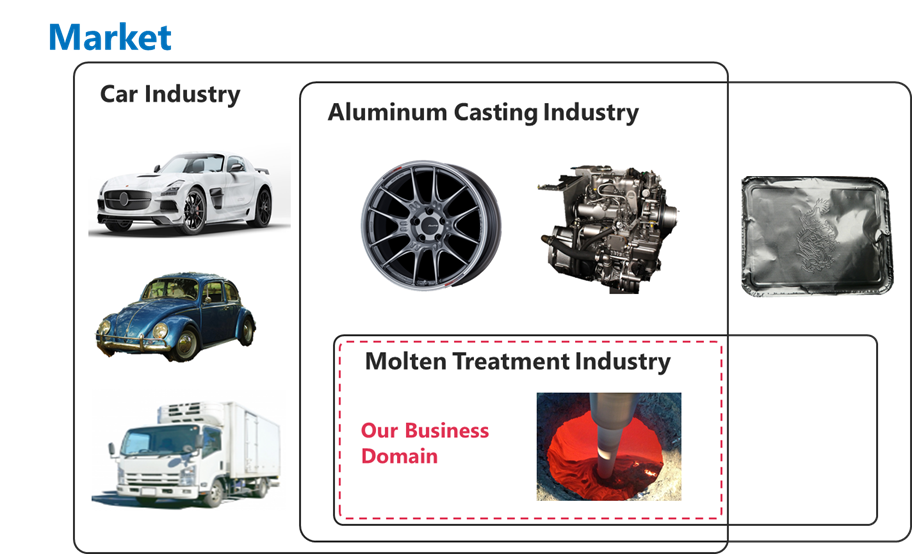

We, Nikkin Flux belongs to molten treatment industry. Our primary customers are aluminum casting maker and aluminum casting department of car maker.

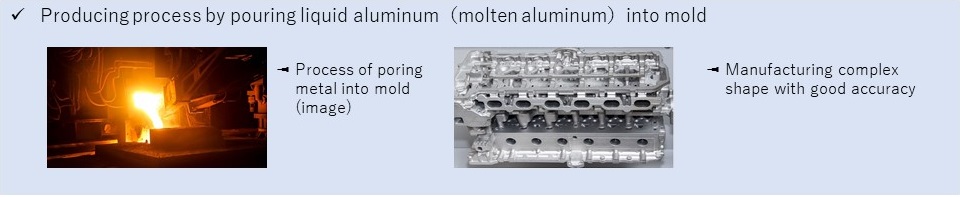

In aluminum casting site, melted aluminum, which called molten aluminum, is poured into mold and produce product. In case molten aluminum contain impurities, it may occur insufficient strength or holes on the surface of product. If it happens, all product which made from this molten become defects.

Thus, it is very important to check the quality of molten and improve the quality before pouring into mold in aluminum casting industry. Nikkin Flux has a wide selection of product in each casting process and in the future, we are aiming at providing total solution for customer by combining our products and statistic process.

Click on a category to go to the corresponding section.

Flux, which we have produced from its foundation, removes oxides from aluminum and improve its mechanical properties. Since the quality of the casting depends on the quality of the molten metal, it is essential to select a good quality flux correctly. And in recent years, the demand for recycled aluminum has been increasing from the perspective of environmental protection, and flux plays an important role in cleaning the recycled material.

We, Nikkin Flux have many years of experience and a wide lineup of fluxes to offer users the proper fluxes.For the details, please refer to the flux list or contact us from contact form.

b.Mother Ingots for Component Adjustment

The feeder supplies flux into the molten aluminum. Rather than sprinkling flux on the surface of the molten metal, direct spraying of flux into the molten metal increases the efficiency of the reaction.Normal feeder adjusts the amount of injecting flux per each only 1kg, but our flux feeder can adjust per each 100g.

The degassing mixer performs degassing by bubbling inert gas into molten aluminum. It is often used in combination with flux because the oxide is efficiently removed by feeding the flux and stirring it in the feeder. We offer a wide range of mixers to meet the needs of our customers, such as durable carbon mixer using silicon nitride, and microbubble generator that reduces hydrogen gas.

In order to check the effect of flux and degassing treatment, quality check equipment is essential in die casting site. The pinhole tester “NK Series” conduct simple visual inspection in front of the furnace. It has been adopted by many major automobile manufacturers in Japan and abroad.

Volcester measures the occurrence of gas cavity in front of the furnace in a short time and with high sensitivity. This system is about 1,000 times more sensitive than the pinhole testers “NK series”, so that it detects small defects accurately. Operation instructions are displayed on the touch screen in an interactive format. The data is stored in USB and can be used for statistical processing on PC.

In the IA500 filtration test, molten aluminum is pressure-filtered and passed through a filter. And the quality of the aluminum is evaluated based on the filtration time and the left substance on the filter such as oxide, foreign matter, and inter metallic compounds.

On the other hand, in the image analysis performed by IA500 and MIRASYS, after filtration test, CCD camera captures digital data of the aluminum cross section on the filter, and analyzes it using our original program. We have been accumulating past data in our database for many years. By checking against this database, it is possible to know the quality level of the aluminum sample in the database relatively.

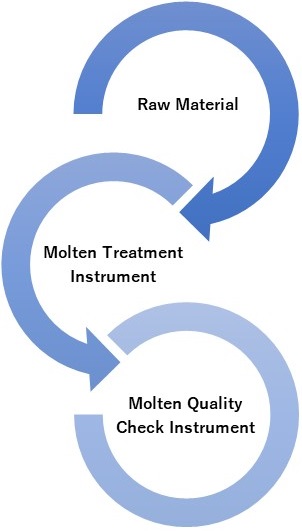

First select raw materials, such as flux and coatings, according to the molten metal conditions. Secondary choice molten metal processing method from feeders and degassing equipment. And check the quality of molten metal and, if necessary, reexamine raw materials and molten treatment methods.

Only Nikkin Flux has the products to support by these 3 steps of molten metal quality. By combining these technologies, we will provide the best solution for problems related to molten aluminum processing.

Basically, we ask you to send aluminum sample which you are using. As soon as the sample arrive, we conduct IA500 and MIRASYS image analysis. Based on the results, we will make proposals for improving the quality of aluminum, such as fluxing, degassing, and installation of inspection equipment.