MIRASYS

Image analysis gives advantages to measure the total inclusion measurement. This analysis is suitable for the aluminum metal quality control, and we supply service inspection for most of automotive companies in Japan.

Image Analysis Procedures

The image analysis is performed through the following steps. To perform image analysis, you need IA500, cutter, resin embedding machine, polisher and MIRASYS.

(1) Filtration Test by IA500

First, molten aluminum is filtered through the filter in the IA500.

Impurities are deposited on the filter after filtration. The aluminum on the filter and the filter itself are taken out of the IA500 as a sample.

(2) Marilite Removal

Cut the Marilite part by contour machine, so that you can pick up the central part from marilite part. The central part is consists of the filter and aluminum.

(3) Cutting of the Central Part

Cut the central part with a cutter. Occasionally, the vibration of the cutter may cause the filter and aluminum parts to separate. Cut with as little vibration as possible to avoid separation.

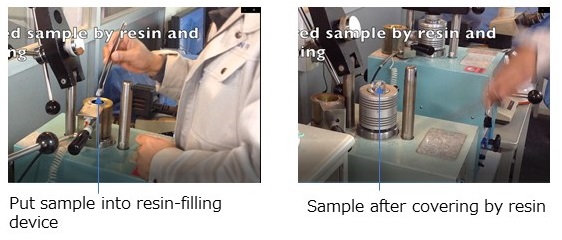

(4) Covering by Resin

Cover the sample with resin and equipment.

(5) Polishing

Polish the cut surface which is cover by resin. General polishing methods are fine.

(6) Image Analysis by MIRASYS

Finally the cross section of the sample is analyzed by MIRASYS.

Image Analysis

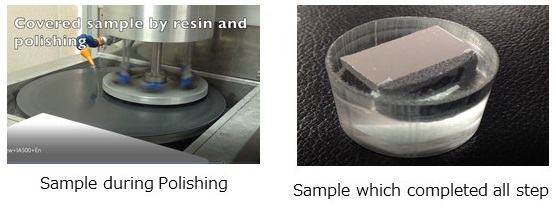

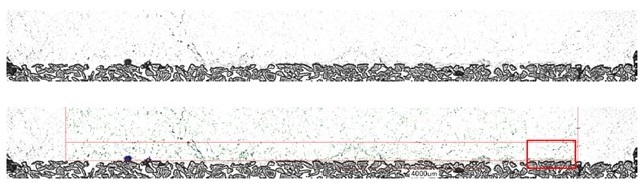

Top and Bottom image

This is an images of top and bottom on the filter.

Inclusions and oxidation is shown on the blue line. Top is the dirty sample, and bottom is clean sample.

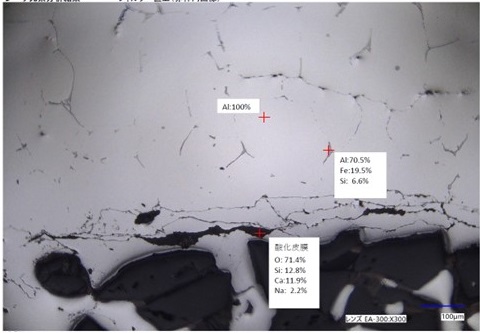

Middle image

This image was photographed in high magnification.

If you looks carefully, green part and blue part are existing.

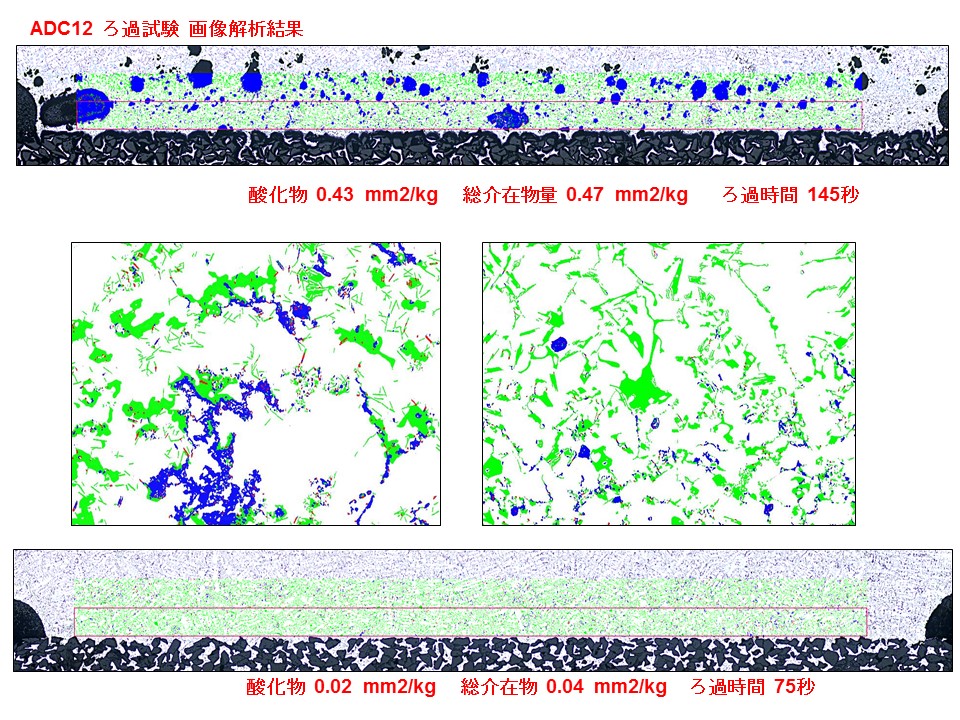

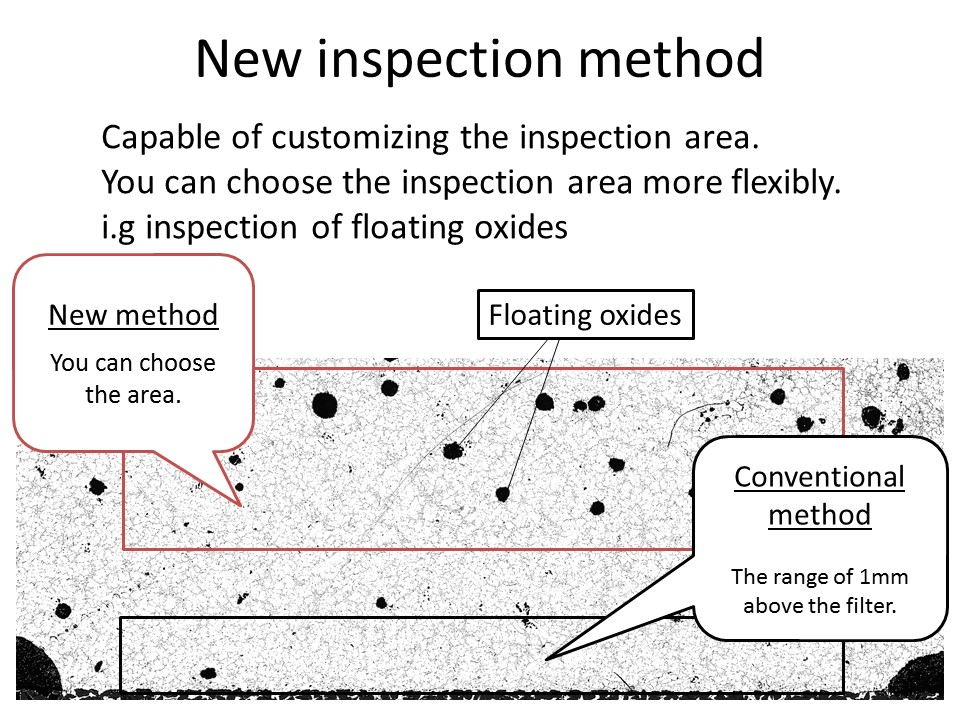

New inspection method

(1)Customizing the inspection area

As left images, you can set the location to measure the sample by your selves. For example, it can be also measure floating oxidation which is not existing at the top of filter This gives us lots of flexibility.

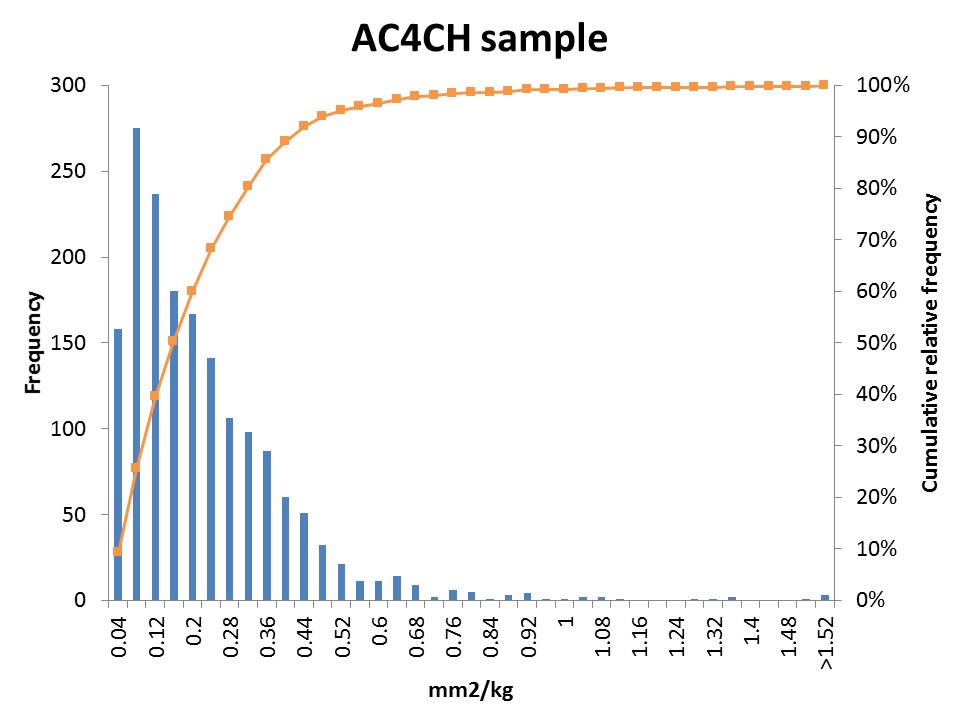

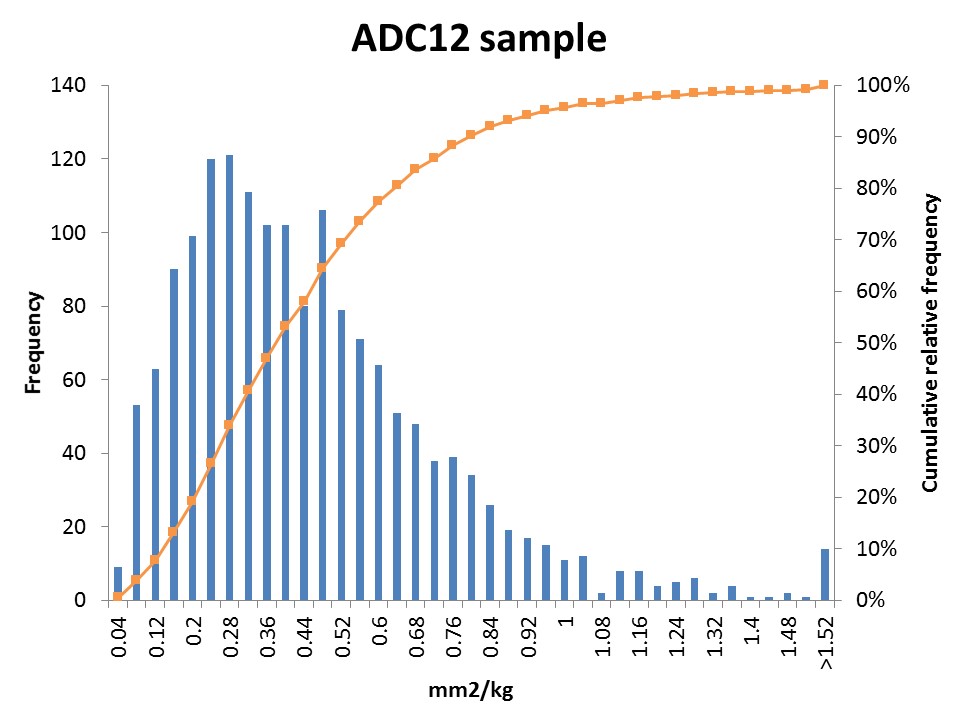

(2)PSD of inclusions

It is possible to analyze the inclusion volume by PSD. So more detail analysis by PSD also possible.

Historical Data Record

Based upon out historical inspected data, now we can consulting the marketing information.

Elemental Analysis Services

Left: Results of elemental analysis by enlarging the area within the red frame in the above figure. The component name and percentage are displayed for each analyzed point.

By identifying the composition of foreign substances, it is possible to check whether there are causes of chipping defects such as oxide film and magnesium oxide.

Inspection Service

We do the inspection service for portrait analysis of inclusion / oxidation measurement by IA500. Feel free to contact us.

When requesting a filtration test, please have more than 3kg per sample. It is ideal if you can offer a 5kg sample.

Also, should you need to prepare a sample in the products, etc., make sure that there is no adhesion of foreign matter on the sample. Especially sand for casting or other metals except aluminum, will be impact in the analysis data.

If you have any questions, please feel free to contact us.