This is quick and high accuracy aluminum quality inspection equipment to check the gas volume and existence of inclusion in the molten aluminum. So performance of degassing treatment can be check before starting the casting.

Volcester STD: W800 x L550 x H1150(mm), 150kg

Introduction Movie (1min, Japanese)

Consistent contents for BB Tester

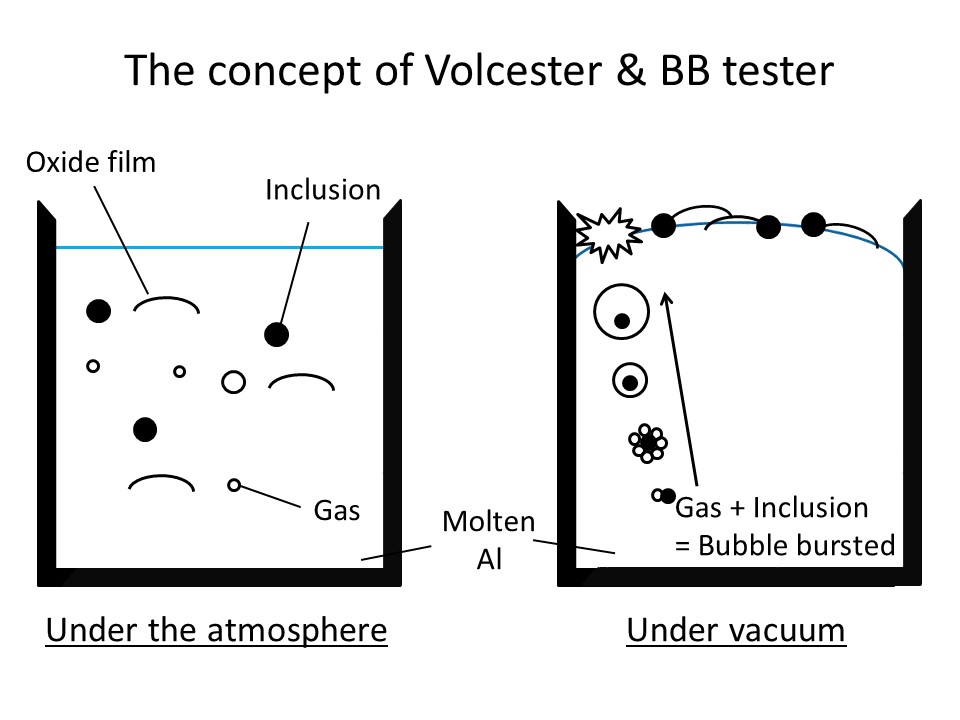

Let the contaminated gas and inclusion / oxidation out from aluminum molten metal by vacuum exhaust process. Gas will be captured by inclusions and became bigger than others. Once the gas becomes bigger, it comes out from molten metal, and baster on the top surface. This equipment can be measure the busted pressure change by vacuum gauge.

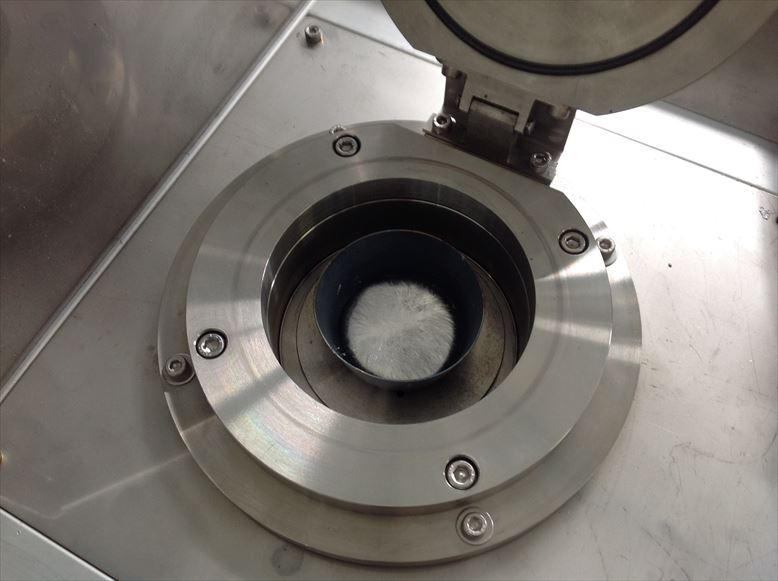

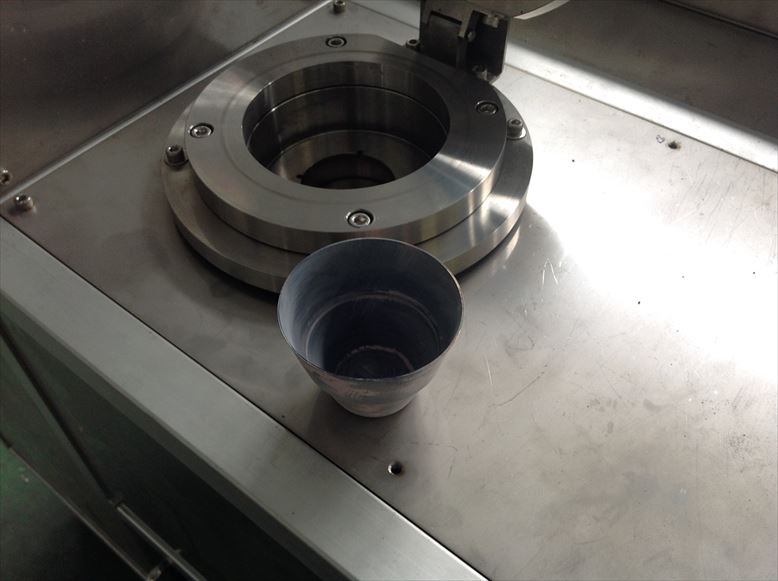

Put the steel cup with 100 g of aluminum molten metal.

Metal sample and inspection screen samples

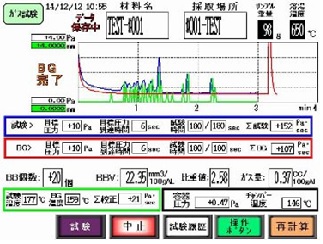

In case of lots of inclusions: Sample surface is busted and recognize lots of gas contamination.

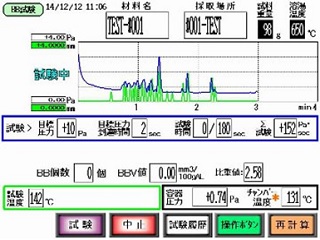

In case of low inclusion: Sample Surface is flat and smooth, and no recognition of bubble.

Type of Molten Metal: ADC12

Inspection Temperature: about 620 degree C

Inspection periods: 180 sec.

Inspection

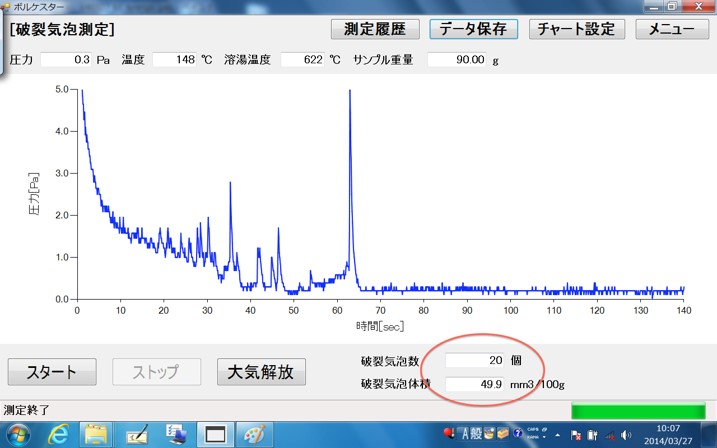

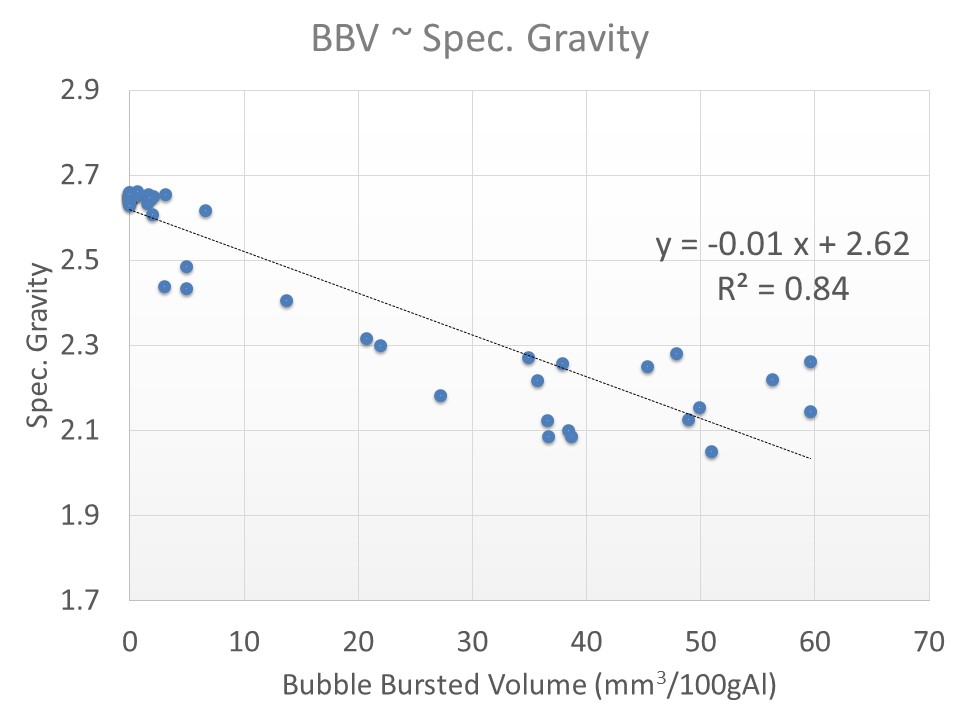

Bubble buster volume measured by BB Tester can be shown how many burst happen during inspection. This remaining bubble an be a cause of pinehole defect.

Bubble busted volume and density of solidification sample has strong correlation as attached left image.

Characteristic of Volcester

Total gas measurement system

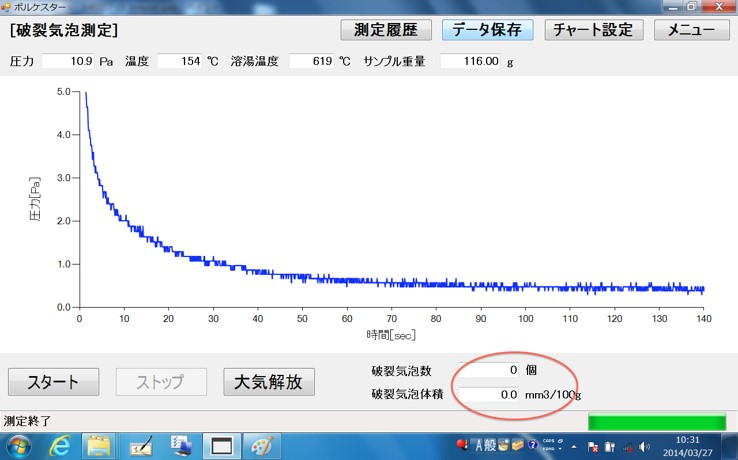

Volcester can conduct a total gas measurement.

During inspection, it can be measure the total gas volume exhausted from sample.

Touch panel operation

Comparison of Volcester HQ and BB tester

We offer you two options, depending on your application. Please refer to the list below to select the type you would like.

| Volcester HQ | BB Tester | |

| Measurement Time | 360sec (180sec for sample measurement+ 180sec for back ground measurement, hereinafter referred to as “BG”) | 180sec (only for sample |

| Oxide Measurement Method | 1. A sample of aluminum is poured into a cup, set in the apparatus and depressurized. The oxide contained in the aluminum expands when the pressure is reduced in the equipment, and it ruptures as a bubble on the surface of the aluminum. At this time, the pressure in Volcester changes. 2.This pressure change is shown by the number of bubble bursts and the volume of gas released. The smaller the pressure change and the lower the amount of oxide content, the better the quality of the aluminum. | Same as left |

| Gas Quantity Measurement Method | 1.The aluminum sample is poured into a cup, set in the apparatus and depressurized. The gas is released from the aluminum sample and the sampling cup. Volcester measures the pressure integral. (First measurement 180 sec) 2.After the first measurement, remove the solidified aluminum sample and return the cup to the machine for BG measurement. (Second measurement 180 seconds) 3. Volcester calculates the pressure integral from the aluminum sample by subtracting the second result from the first measurement. 4. At the end of the second measurement, calibration gas is released into Volcester. This pressure integral and the amount of gas from the sample obtained in 3 are substituted into the ideal gas law. The amount of gas in the aluminum sample is calculated as 0.xx cc/100 gAl. Ideal Gas Law PV=nRT | 1.Set the aluminum sample and cup in the apparatus as in 1. on the left, and measure the pressure integral. 2.Create regression equation for the correlation based on the Lansley test results in advance. Substitute the pressure integral of 1 into that regression equation in order to calculate the gas volume. |

| Equipment Characteristics | Volcester has calibration and bag-ground measurement functions. It is often used in laboratories to measure less than 0.18cc/100gAl. | BB tester measures the presence or absence of oxides from bubbles in front of the furnace. No calibration or back-ground measurement function. Cannot measure below 0.18cc/100g. |

| Purpose of Use | Quality evaluation of molten aluminum with little carbon, such as high-purity aluminum and pure aluminum at plant. | Quality evaluation of die castings and cast alloys at plant. |

If you have any questions, please feel free to contact us.