This device is developed to measure the gas contents of aluminum molten metal by specific gravity, which is related to the metal’s grade. In case of high quality aluminum casting, surface defect cause by remaining gas hole called “pinhole” is one of the major concern of defect. Knowing the volume of gas contamination in the molten metal is one of the most important factors of next treatment, degassing treatment.

・Able to predict the risk to get pinhole defect from Hydrogen gas.

・Measurement time is about 5 minutes.

・The exhaust flow volume and the time required to reach target pressure are adjustable.

・It is introduced at low cost.

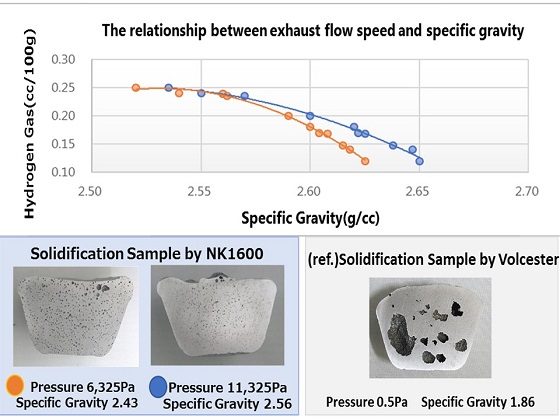

Solidified sample by pinhole test NK1600.

The specific gravity differs depending on the exhaust flow gas volume.

By adjusting pressure reduction conditions, you can conduct solidification test under the high correlation with defect rate of your products.

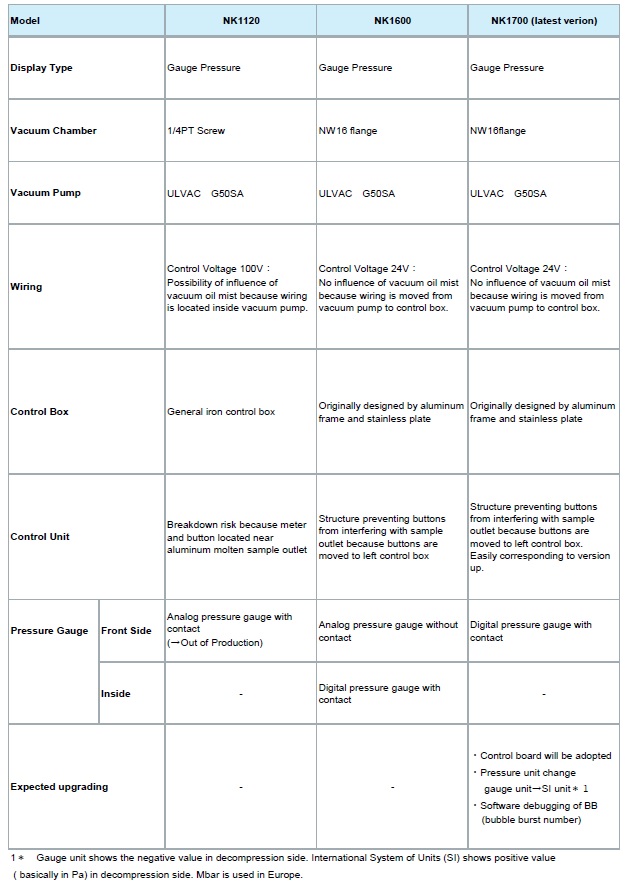

NK1600 will be replaced by NK1700

If you have any questions, please feel free to contact us.