The degassing mixer is a mixer to degas by bubbling inert gas into molten aluminum. The mixer is used with flux to remove oxides efficiently. The mixer cleans molten metal to the new-ingot level and contributes to cost reduction. It is used by attaching it to degas processing equipment.

Features of Nikkin’s Degassing Mixer

1.High degassing effect

2.A wide variety of mixers are

3.Anti-oxidation treatment (impregnation treatment) on the surface of the mixer

4. Made of high quality domestic carbon

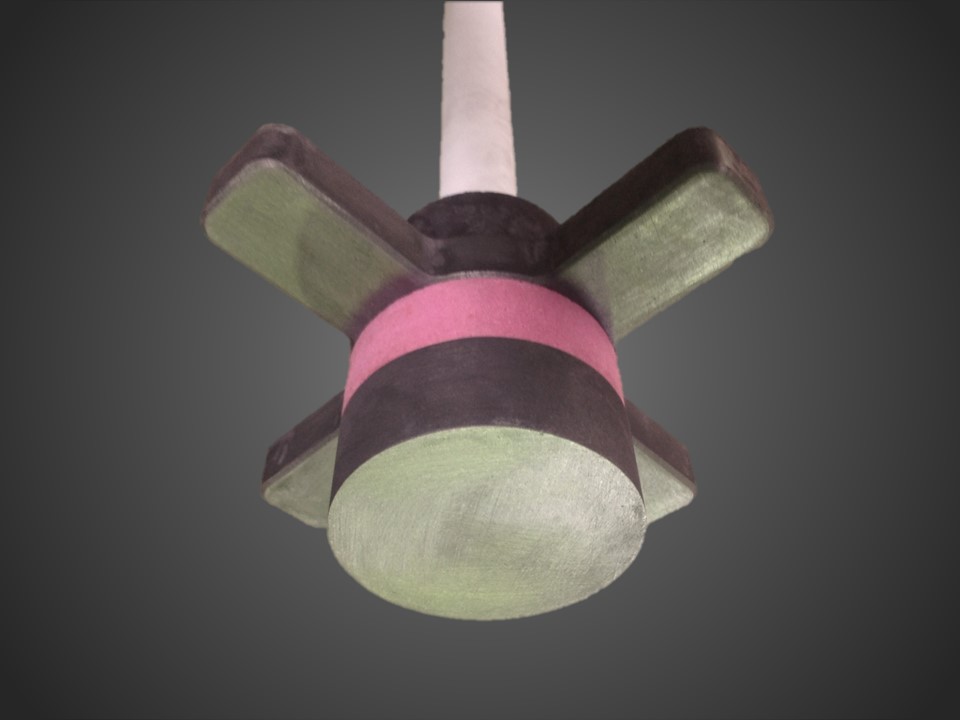

Carbon Mixer

Carbon mixer with bubble crashing method. We supply customized carbon mixer based upon your furnace and frange drawing or current create drawing from existing mixer. Application: inline degassing equipment.

Max size: Shaft: Carbon (OD80 x L1000mm) Impeller : Carbon (OD240mm)

Production leadtime: 1-2weeks

ALPUR SS Mixer

Ceramic mixer with bubble crashing method. Application:

inline degassing equipment, furnance

Insert Gas:

Ar or N2 30L/min (0.3MPa)

Frange:

EG Type (PCD110 6-OD11)

Material:

Shaft: SIALON (OD55 x L1200mm) Impeller : Super SIALON (OD240 x L40mm, 8 Impellers)

ALPUR3 Mixer

Ceramic mixer with bubble crashing method. Application:

Ladle, Holding Furnace

Insert Gas:

Ar or N2 5 – 10L/min (0.3MPa)

Frange:

EG Type (PCD110 6-OD11)

Material:

Shaft: SIALON (OD35 x L1000mm) Impeller: Super SIALON (OD240 x L40mm, 4 Impeller)

ALPUR EG Mixer

Carbon CT mixer with homogeneously distribute of micron bubble. Application:

inline degassing equipment, Holding Furnace

Insert Gas:

Ar or N2 10 – 20L/min (0.4MPa)

Frange:

EG Type (PCD110 6-OD11)

Material: /b>

Adapter, Impeller, Screw Nut: Carbon Shaft: SIALON Porous Ring: Hi-Alumina

If you have any questions, please feel free to contact us.