EN

EN

Products

Product Lineup

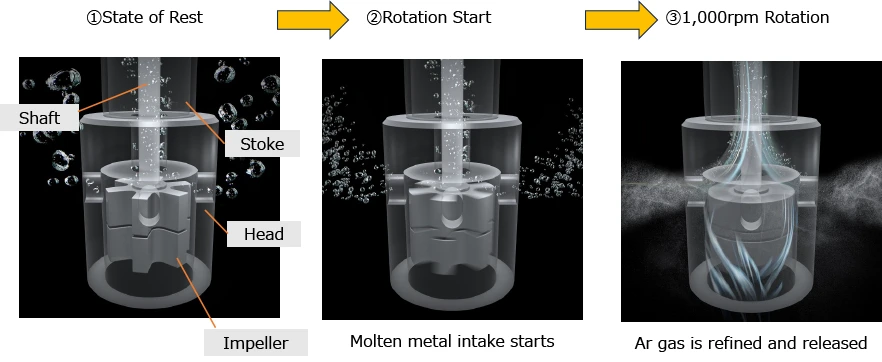

The original structure produces finer air bubbles than conventional mixer, resulting in a high degassing effect.

The impeller is not exposed and the head is small, allowing installation in confined spaces such as around immersion heaters and downspouts.

Installation sites are hand furnaces, LP furnaces, and light pressure plant gutters. It prevents oxide buildup in furnaces and tube heaters.

Possible to reduce the use of process gases such as Ar, etc. When controlled at 1 liter/minute or less, a manometer must be provided separately.

Caution: We recommend that molten metal with a lot of dross and foreign matter be treated with flux beforehand to prevent damage or stuck impeller parts rotating at high speeds.

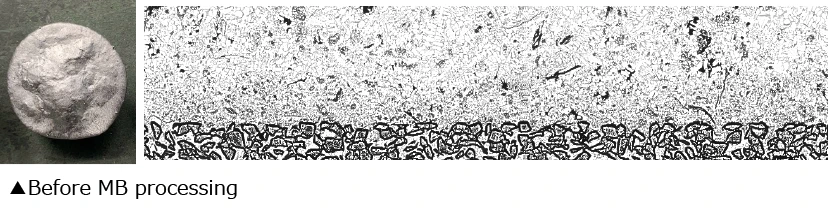

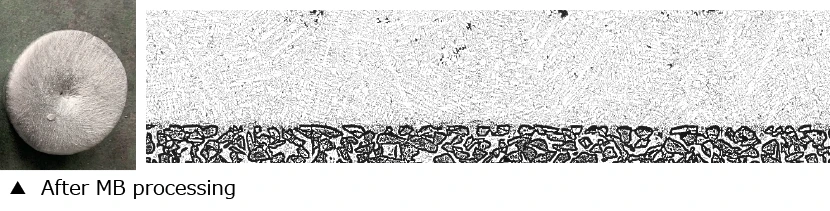

Image above the filter after filtration test